We help Loire Gestamp detect and identify anomalous operating patterns that affect their production process.

Challenge

Loire Gestamp, one of the world’s leading manufacturers of hydraulic presses for the automotive industry, was interested in analyzing and characterizing the performance of the auxiliary pumps of the presses it manufactures. The goal was to detect and identify anomalous operating patterns that could negatively affect the efficiency of their hot stamping installations, the quality of their production, and unplanned press shutdowns. Ultimately, they aimed to detect anomalies in advance, enabling them to implement effective predictive maintenance strategies.Project

Our proposal focused on achieving these three objectives:

- Detect anomalies in the operation of the auxiliary pumps.

- Identify the probable origin of each anomaly.

- Implement an application for the automatic, cycle-by-cycle analysis of the presses’ operation using an IIoT (Industrial Internet of Things) platform.

The supervision and diagnostic system we developed, in collaboration with the UPC MCIA Research Center (Motion Control & Industrial Applications), is based on procedures that analyze variables accessible on the machine. These procedures are supported by advanced signal processing techniques and artificial intelligence methods. They enable us, on one hand, to characterize the current operating state of the pump, and on the other, to detect and identify failure patterns observed over time.

For the implementation of the final solution both for ingesting data from the press signals and deploying advanced analytics techniques we utilized the IoT MIIMETIQ platform from Nexiona. On this platform, we developed:

- The ingestion of data from the press signals under study.

- All quality auditing, segmentation, and filtering operations to generate the datasets that feed the diagnostic algorithms.

- The implementation of advanced analytics and artificial intelligence algorithms used in the project.

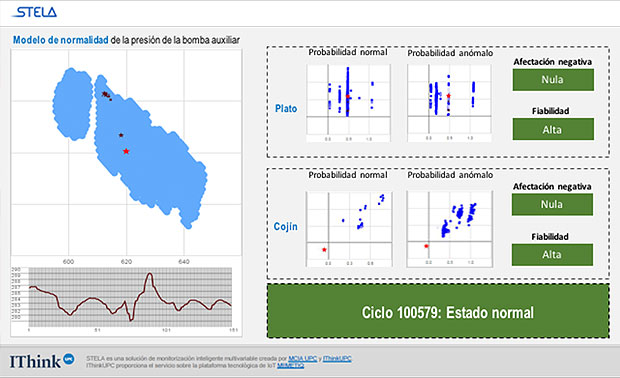

- The final results visualization application, called STELA, synthesizes the information from 30 press signals sampled at 100 ms into easily interpretable graphs for plant operators, and slightly more detailed ones for plant engineers and data analysts.

Results

In this link, we present the descriptive report of the entire project.

The most significant benefits that this project has provided to Loire Gestamp are:

- Loire Gestamp now has a tool that automatically and autonomously analyzes and monitors hundreds of thousands (or even millions) of production cycles. It can quickly identify abnormal cycles and analyze the likely causes of any issues through both forensic analysis and real-time analysis.

- The STELA application, developed on Nexiona’s MIIMETIQ platform, enables press operators, plant supervisors, press setup teams, and plant engineers to quickly detect anomalies in press configurations—regardless of the manufacturer’s reference or the press being monitored. It also provides a simple interface for plant operators and a detailed interface for plant engineers or data scientists to visualize the results.

- Loire Gestamp has the ability to quickly identify problems of the auxiliary pump in case of abnormal operation.