Smart manufacturing, predictive maintenance, production optimization, pull planning with digital Lean tools, energy efficiency, operational excellence, and more.

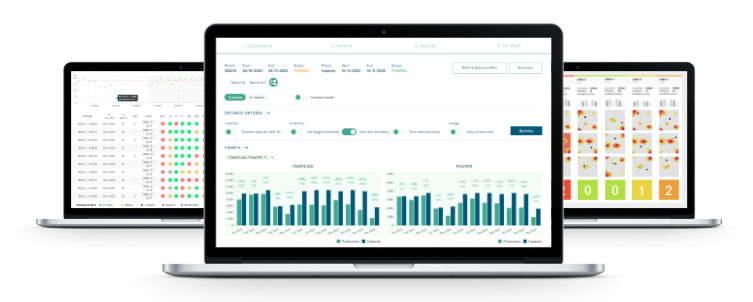

We design and deploy unified platforms combining IoT, edge computing, and data analytics in industrial environments, enabling the monitoring of any variable from a machine or process. In our projects, we integrate multiple data sources, analyze trends, and detect behavioral patterns, allowing us to deliver tailored advanced analytics solutions for predictive maintenance, process efficiency, or product quality.

We create AI-based solutions tailored to each client to optimize planning, manufacturing, and distribution processes with a global perspective.

Some of our solutions also include mathematical modeling (MILP, ILP) applied to demand forecasting and production planning, combined with heuristics and metaheuristics (GRASP, simulated annealing, genetic algorithms, etc.) to, for example, optimize the sequencing of production processes.

Our partnership with FICO enables us to carry out projects involving mathematical modeling (MILP, ILP) applied to demand forecasting and production planning, combined with heuristics and metaheuristics (GRASP, simulated annealing, genetic algorithms, etc.) to, for example, optimize the sequencing of production processes.